SE-DUZ Series Injection Unit Features

Sumitomo (SHI) Demag's new SE-DUZ direct-drive all-electric injection molding machines offer an even wider choice of injection units than the predecessor SE-DU Series. This selection of injection units combined with the advanced, low inertia design of the injection unit's direct-drive motors provide:

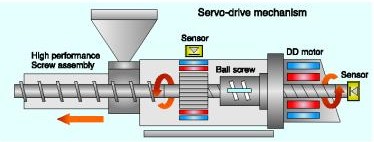

This diagram shows the compact, low-inertia, direct-drive configuration of the SE-DUZ injection unit. The motor for injection uses a load cell to provide feedback that dictates the speed and torque required for precision injection pressure. The screw drive motor works together with a position transducer.

The high torque of the direct-drive, screw drive motor, as compared with a belted motor, is a particular advantage for high-viscosity resins. And compared with a hydraulic machine, the SE-DUZ requires fewer control devices because there are no proportional and directional valves needed to control hydraulic flow and pressures.

Working together with the new Z Control, the SE-DUZ delivers improved precision with low-pressure filling. The Z's patent-pending Flow Front Control (FFC) System optimizes the flow front, further allowing control of low internal pressures inside the cavities. This system:

The SK-II, the industry's most advanced injection control, is also available to help molders achieve the highest levels of injection fill precision and peak pressure stability. (Control software standard; screw tip optional.)

Superior temperature control, provided by the following features, is another advantage of the SE-DUZ:

Other SE-DUZ injection unit features include:

For specifications and to read more about SE-DUZ Series injection molding machines, please use the Info buttons above at the right.

SE-DUZ INFO

Brochure pdf

Specs Chart pdf

Van Dorn Demag is a proud brand of Sumitomo (SHI) Demag.

Van Dorn Demag is a proud brand of Sumitomo (SHI) Demag.