SE-DUZ Series Clamp Features

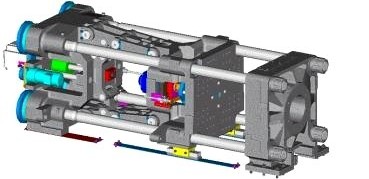

Sumitomo (SHI) Demag's SE-DUZ Series direct-drive all-electric injection molding machines ensure the highest levels of clamping performance with:

SE-DUZ clamp operation also provides the capabilities needed for a wide range of applications. Multi-stage mold open/close speed control can be used to tailor machine operation to specific mold requirements. Excellent clamp force linearity, from low to high tonnage, enables optimum setting of clamp force to suit parts with different projected areas. Additionally, selectable auto-ramping modes can be used to optimize clamp open and close profiles for fast cycling with shock-free movement.

Plus, mold protection is never an issue with the SE-DUZ. With low pressure mold protection settable to 0.3mm, and mold open/close positions settable to 0.1mm, precision mold protection is ensured and there's no banging - even at high speeds. Mold open stop position accuracy of 20 microns, an important factor for take-out robots and 3-plate molds, is ensured with monitoring by precise optical encoders and full closed-loop control.

Features supporting fast, easy mold changeovers include:

Multi-toggle clamp force control, a standard feature on the SE-DUZ, offers two modes:

For optimum life of the ball screws, toggle pins and tie bar bushings, the SE-DUZ is equipped with a highly reliable, automatic grease supply through a valve-type progressive distribution system that uses easy-to-load grease cartridges that can be changed on-the-fly.

For specifications and to read more about SE-DUZ Series all-electric injection molding machines, please use the Info buttons above at the right.

SE-DUZ INFO

Brochure pdf

Specs Chart pdf

Van Dorn Demag is a proud brand of Sumitomo (SHI) Demag.

Van Dorn Demag is a proud brand of Sumitomo (SHI) Demag.