SK-II Control

Sumitomo (SHI) Demag takes injection molding precision to the next level with its SK-II Control Option, the industry’s most advanced injection control.

The SK-II Control option provides a specially designed screw tip assembly and control software. Available only on Sumitomo SE7M, SE-DUZ and the new SE-EV Series all-electric injection molding machines, the SK-II:

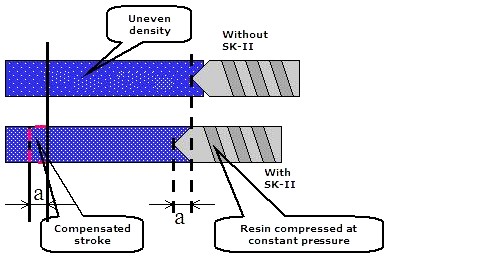

How it works — On completion of recovery, the check ring is mechanically sealed, completely shutting off material flow (or back flow). Pressure is then put on the screw to drive it forward prior to injection. When the pre-set pressure is reached, the machine control records the position of the screw. The correction for this volume is made on the next shot and the full shot position is adjusted accordingly. The pressure and speed at which the forward motion occurs are set on the SK Control screen.

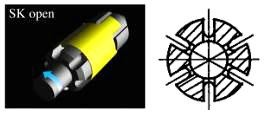

During plasticizing, screw rotation allows the check ring and seal to align so the channel is open for melt flow.

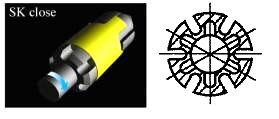

On completion of recovery, the screw counter-rotates to block the flow channel, and the channel remains blocked during screw pullback and fill.

The SK-II is well-suited for a wide range of engineering resins and regrind. Applications include connectors, lenses, packaging, office automation, media and other high-precision parts.

For improved durability against abrasion and corrosion, a proprietary coating is also offered for the SK-II.

Van Dorn Demag is a proud brand of Sumitomo (SHI) Demag.

Van Dorn Demag is a proud brand of Sumitomo (SHI) Demag.