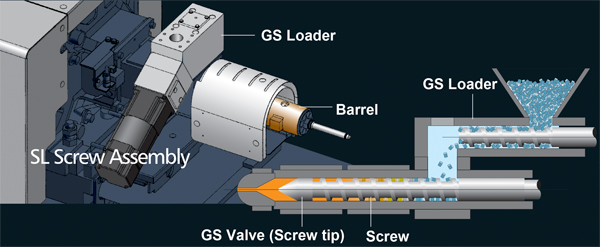

The SL Screw Assembly

In traditional injection molding, shear heat develops due to dragging resistance of the resin between the screw flights and the barrel. This causes fluctuation of the molten resin density and various other problems. The SL (Spiral Logic) screw assembly avoids these problems by eliminating shear heating instability.

Benefits of the SL screw assembly include:

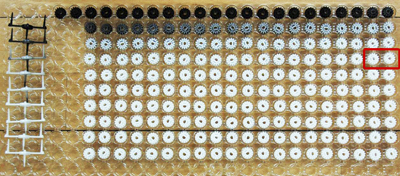

The SL screw assembly also allows exceptionally fast color and/or resin change out. In the two-cavity mold example shown here, the 40th shot shows complete changeover from black to white.

The SL screw assembly is selectable as a standard option on Sumitomo (SHI) Demag's new SE-EV Series advanced all-electric injection molding machines and as an option on the SE-DUZ direct-drive all-electrics.

Van Dorn Demag is a proud brand of Sumitomo (SHI) Demag.

Van Dorn Demag is a proud brand of Sumitomo (SHI) Demag.