Systec Series Hydraulic Injection Molding Machines

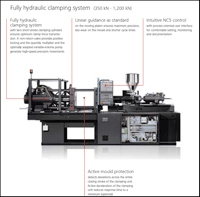

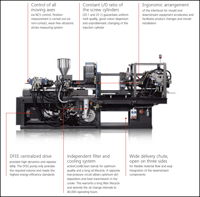

BENEFITS AT A GLANCE

Click on photos above for additional information.

Sumitomo (SHI) Demag's Systec Series is the hydraulic-toggle that offers high-end performance at a very competitive price. Available in model sizes from 39 to 2248 U.S. tons, the Systec features a rugged and compact design that accommodates large and heavy molds.

Designed to provide high performance with lower operating costs, the Systec features highly dynamic DFEE pumps that consume considerably less energy compared to standard drives, and the oil-bypass-style cooling and filtration circuit extends oil service life to 25,000 hours ó up to five times the norm.

Machine Highlights

For additional information on the Systec Series of hydraulic-toggle injection molding machines, please click on the Benefits at a Glance photos above or refer to the Systec brochure link above at the left.

Van Dorn Demag is a proud brand of Sumitomo (SHI) Demag.

Van Dorn Demag is a proud brand of Sumitomo (SHI) Demag.