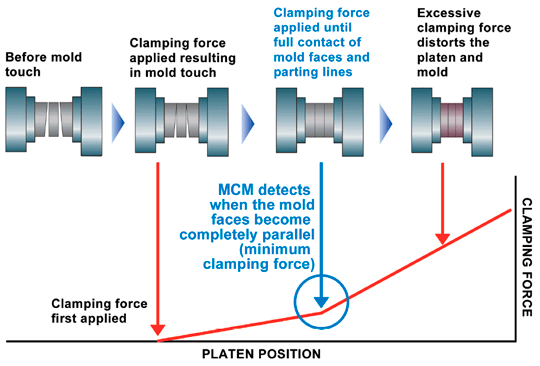

MCM helps molders improve part quality while reducing clamp force requirements. When the MCM system is switched on, the machine automatically detects the minimum point at which the mold halves are completely parallel and surface pressure is evenly distributed across the mold faces.

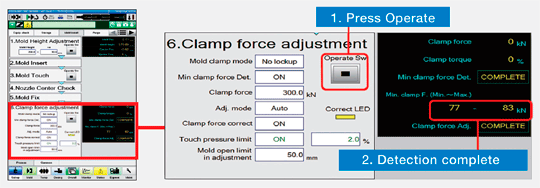

Auto MCM is selected on the one-page Mold Setup screen. Using the detected MCM values and knowledge of the molding process, the desired clamp tonnage is entered.

MCM System benefits include:

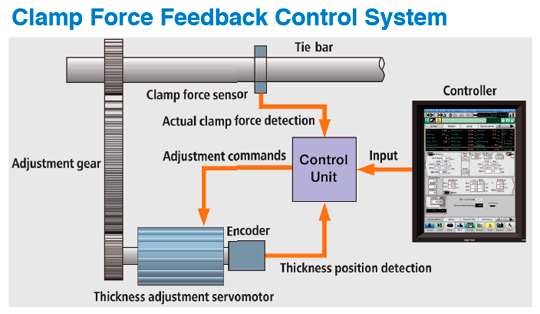

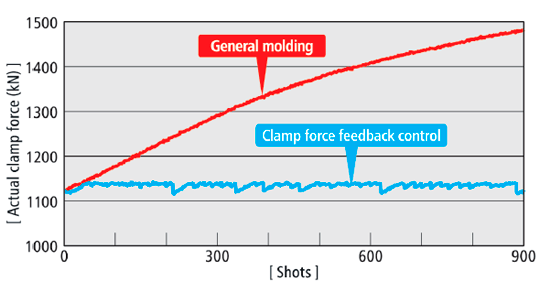

MCM works together with the machine's Clamp Force Feedback Control System (below). This system continually monitors clamp tonnage using a sensor on the tie bar to measure actual clamp tonnage. Unlike systems that rely solely on measurement of the mold space, this system works together with a control device, encoder and a high-performance servomotor, automatically compensating for thermal expansion of the mold and keeping clamping force constantly stable.

Please use links at left (or below on phone) for information on Z-Molding's other systems.

Van Dorn Demag is a proud brand of Sumitomo (SHI) Demag.

Van Dorn Demag is a proud brand of Sumitomo (SHI) Demag.