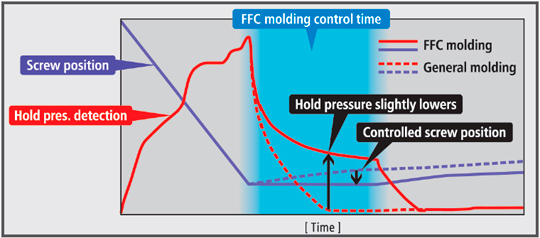

FFC, working together with the ISC II (Intelligent Servo Control) and the direct-drive injection motor, achieves complete and balanced filling with reduced injection pressure. The system takes advantage of the energy and viscoelastic properties in the flow front of the resin to complete filling in an even fashion as opposed to forcing material into open areas and thus flashing the areas that are already filled.

Advantages provided by FFC include:

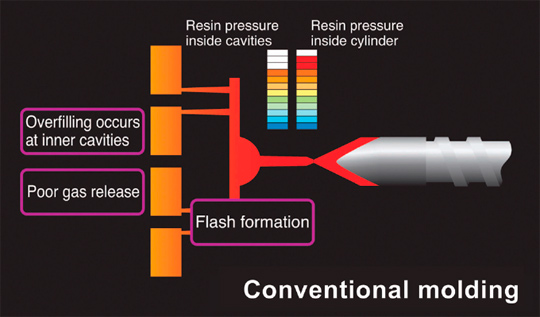

In conventional molding, by forcing resin into the mold cavities, overfilling and compression occur at the inner cavities and gases are trapped.

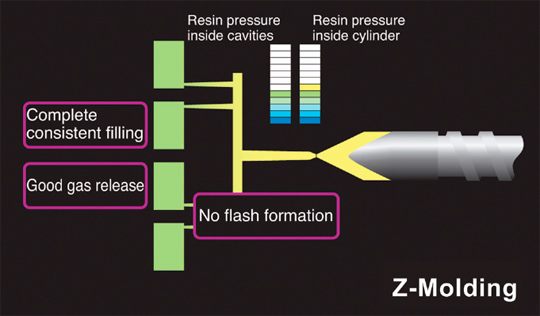

FFC precisely controls screw position at VP switchover to balance fill speed and pressure across all cavities. Problems associated with overfilling and trapped gases do not occur.

Fast response control of speed and pressure before and after VP switchover allows complete filling with low pressure.

Compared with standard molding, FFC achieves complete filling with no flash at the same injection pressure.

Please use links at left (or below on phone) for information on Z-Molding's other systems.

Van Dorn Demag is a proud brand of Sumitomo (SHI) Demag.

Van Dorn Demag is a proud brand of Sumitomo (SHI) Demag.