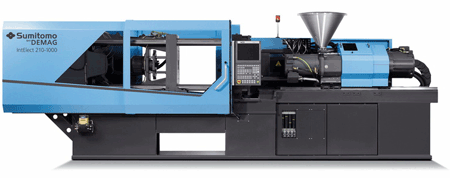

IntElect Series

Direct-Drive All-Electric Injection Molding Machines

BENEFITS AT A GLANCE

Click on photos above for additional information.

Sumitomo (SHI) Demag's IntElect Series of direct-drive all-electric injection molding machines are available in 7 model sizes from 56 to 506 U.S. tons. Its fully-electric machine concept is based on innovative direct-drive technology. Direct-drive machines offer increased energy efficiency and exceptional responsiveness, ensuring higher levels of precision and repeatability.

The increased efficiency delivered by direct drives means that they use considerably less energy than hydraulic machines. And because electric drives generate less heat than their hydraulic counterparts, they require less cooling, further reducing the burden on your electrical infrastructure and the investment required when building new premises.

The IntElect is available in two versions: Smart and Performance.

Smart Version

Performance Version

For additional information on the IntElect Smart and IntElect Performance, please click on the Benefits at a Glance photos above or refer to the IntElect brochure link above at the left.

.IntElect Info

![]() Specifications - Coming Soon

Specifications - Coming Soon

Brochure pdf

Van Dorn Demag is a proud brand of Sumitomo (SHI) Demag.

Van Dorn Demag is a proud brand of Sumitomo (SHI) Demag.